Upper Westside Condominiums

Upper West Side Condominiums

Luminous Enclave

Location: Oakville, ON

Client: llbylV Design

Manufacturer: Viso Lighting

THE BRIEF

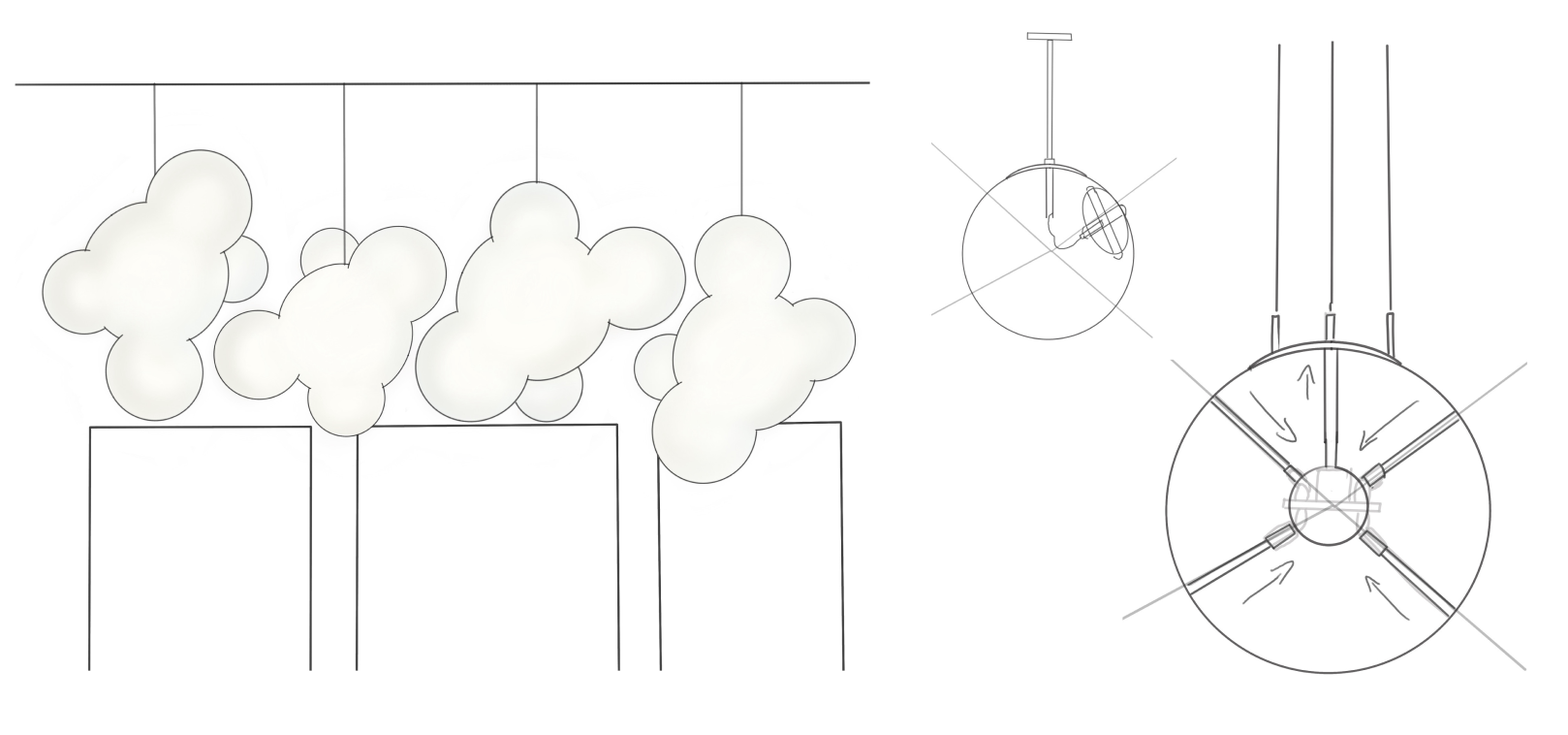

Design the lobby and amenities lighting of luxury residential condominiums to resemble clouds floating in a natural skycape. The clusters must be of seamless and geometrical appearance with no light leakage or visible hardware.

EXPLORATION

Acrylic globes were established to be the main body of the fixture clusters to create the desired geometrical cloud effect. In order to have no visible hardware the internal components had to be located in the centre of the main globe. The initial idea was to have metal brackets attached at the seams of the external globes to the main globe with electrical wiring directed to a central hub.

PROTOTYPING

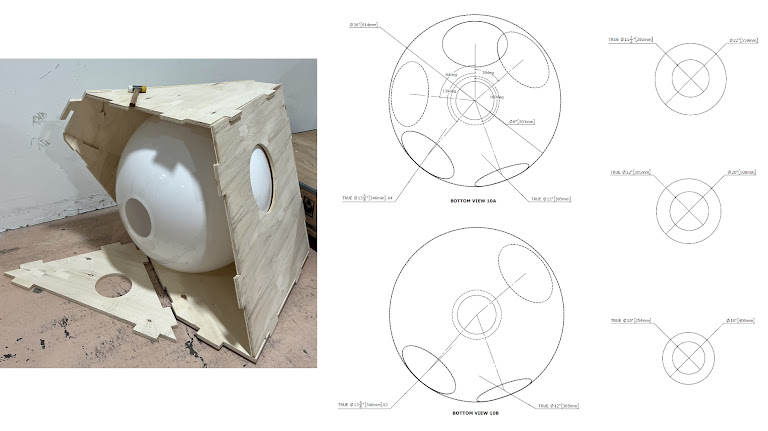

Prototype 1: The prototyping process started by testing how the light would behave inside of two globes joined together. We also tested for potential warping, light leakage and temperature levels during extended periods of time of the fixture being lit up. These findings were recorded and influenced the design of the second prototype.

Jig Prototype

A jig was created to have the precise location of the openings marked on the main globes before they were sent out for cutting. This step was one of the most crucial to ensure the precision of the cuts and success of the final assembly.

Prototype 2

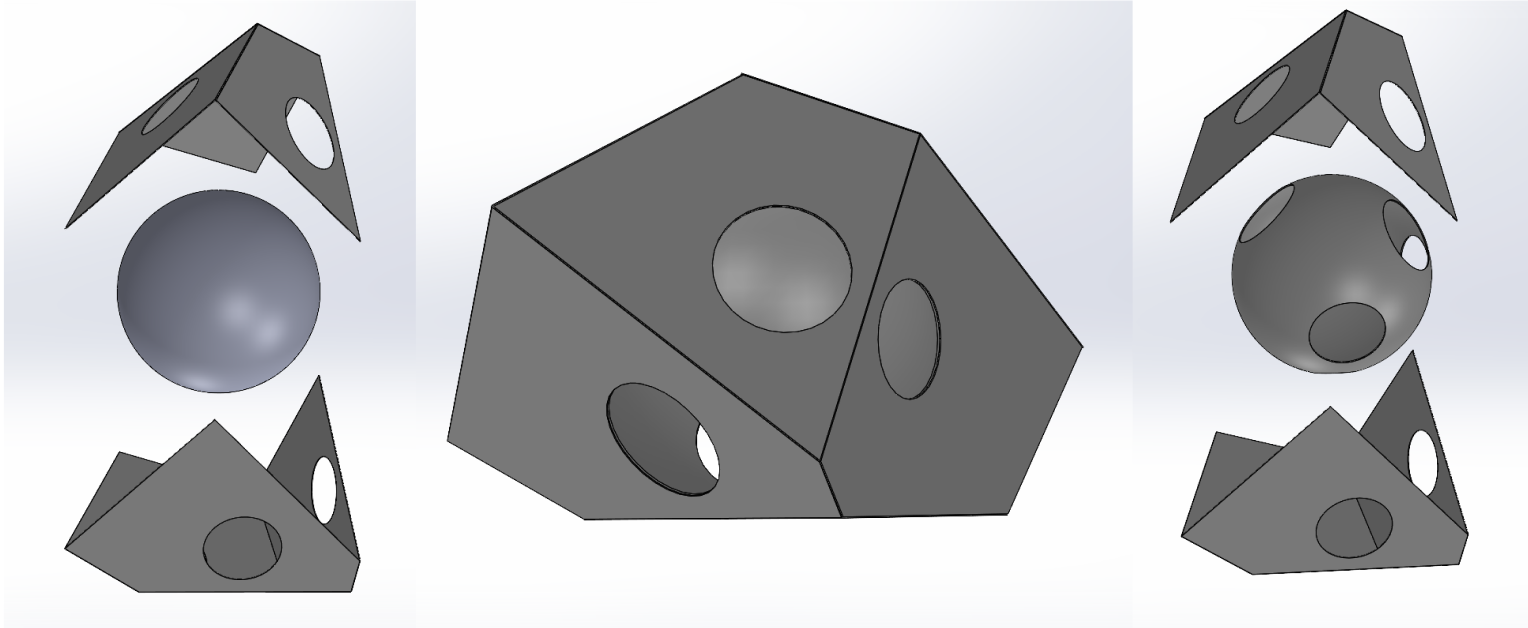

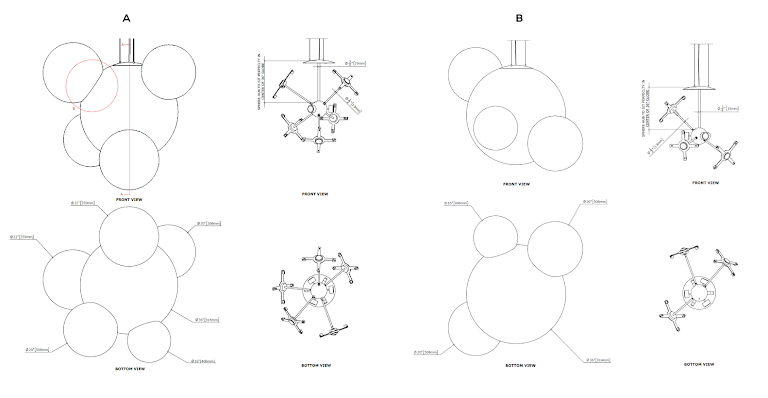

Once the globes were precisely cut we started to test ways to hold the globes and internal lighting components together using a variety of fasteners, 3D printed brackets, metal arms and threaded rods.

A repetition of trial and error and CAD refinement was part of the process to secure the first attachment globe to the main globe.

The fastening process was replicated to the rest of the globes from the inside of the main globe through the opening located at the top where it attaches to the stem and canopy that hold the weight of the fixture. The findings and feedback from IIBYIV were gathered to refine the concept further, eliminate balancing issues and any visible shadows created by the internal hardware.

FINAL DESIGN

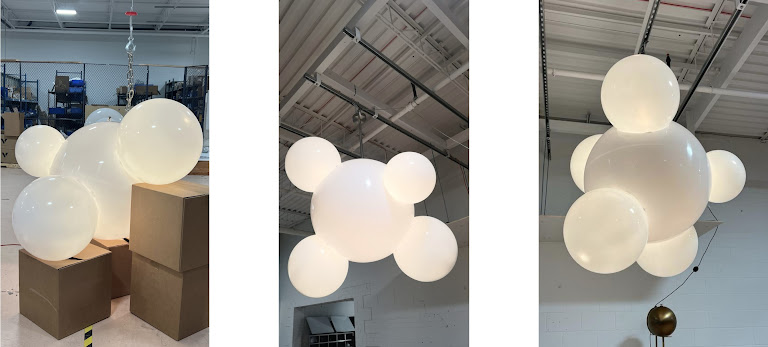

Two versions had to be created to achieve the desired look and aesthetic of the clusters, and allow their close proximity to each other within each space.

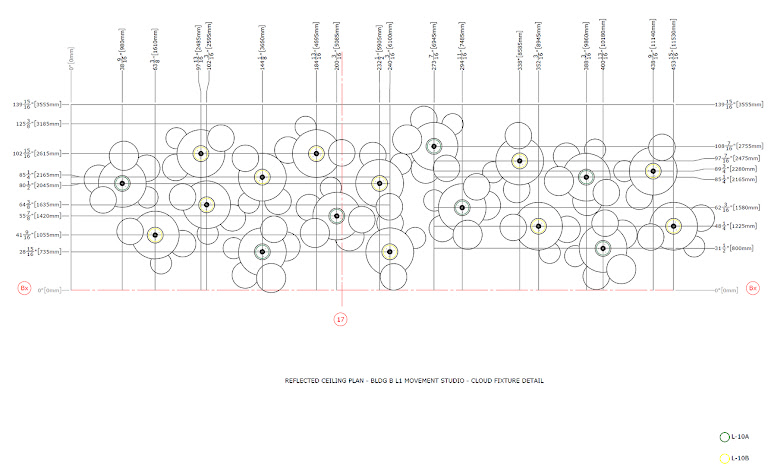

Both variations had the same main globe diameter, only different opening sizes, location, and 3 variations of globes attached. The initial jig was further refined and hinges were added to ensure even more precise hole locations. The same jig was used to mark both A and B globes.

To eliminate stability and weight distribution issues, three aircraft cables replaced the single stem that held the fixture to the ceiling in the second prototype. A central globe with threaded rods was used to attach and create inward pressure to hold the surrounding globes in place. Both A and B configurations were designed to have identical internal components with the only difference being that B had less globes and different sizes attached making them visually distinct. This solution helped Viso significantly reduce manufacturing costs.

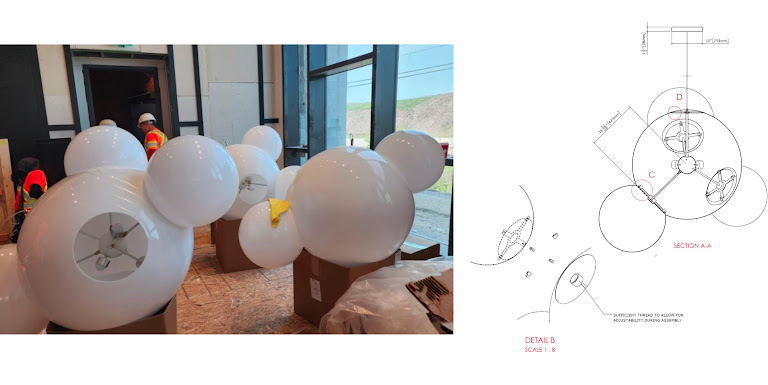

INSTALLATION

The attachment globes had to be assembled on site, as the overall fixture dimensions exceeded the size of the door openings. This challenge was addressed by having the metal arms fixed at the seams in the attachment globes, and adding thread to the integral LED heatsinks, allowing all the electrical and structural components to arrive pre-assembled.

FINAL RESULT

Photography by David Whittaker